|

|

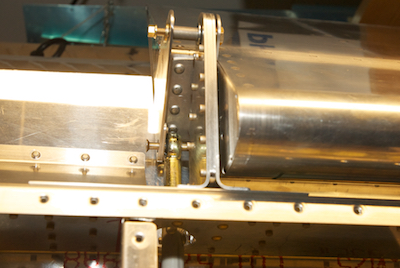

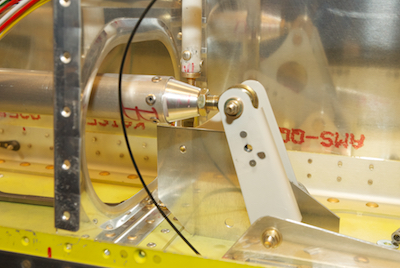

With the tubes assembled and adjusted to the length called out in the plans, you attach the tube to the aileron and the aileron bell crank. In the second picture you can see a jig that is used to adjust the mechanism. The jig is flat against the spar and the bolt holding the other end of the short pushrod to the bell crank is run through the hole in the jig. This holds the bell crank in the neutral position. In picture three another jig is placed on the end of the wing with a bolt through it and a tooling hole in the end rib and another hole centered on the nut and washer holding the aileron in place. You adjust the length of the short push rod until the aileron is aligned with the jig. In my case it took a half turn of one of the bearing ends. |