|

|

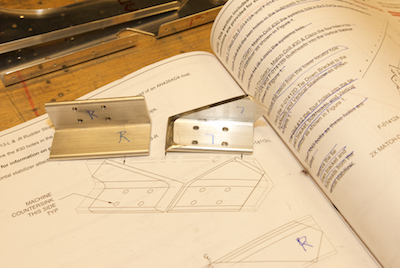

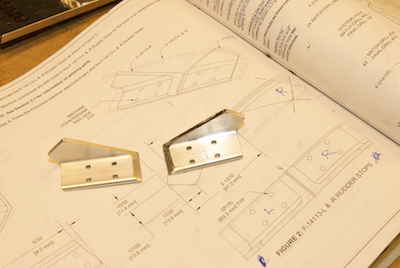

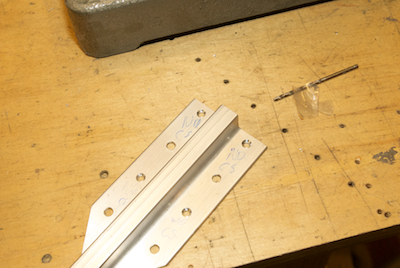

The first two pictures show some angle pieces that needed to be made. I made trivial pieces like these by the boatload for the Sonex. However, I did not like how I had to do these. Instead of giving me raw stock, they give you a piece of stock with the holes, ALREADY drilled! That requires you to make the cuts in the correct position around the holes. What a stupid way to do this. I wouldn’t be much of an airplane builder if I couldn’t make the piece and not locate the holes and then match drill them into the piece they attach to. It was not too difficult, just unnecessarily so. For the third picture I had to get the vertical stabilizer out of storage to match drill some bolt holes. After disassembly, you can see some of the holes in the piece in picture four. If you look real close you can see the notation I made on the piece to not drill the countersinks on this side of the piece. Looking even closer you can see I drilled countersinks on this side of the piece immediately after marking the piece. What did I say about not being much of an airplane builder? |