|

|

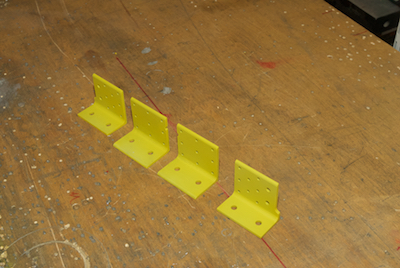

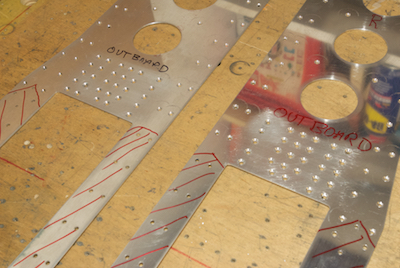

Additionally all of the interior skin stiffeners need to be cleaned up and made ready for installation. The four pieces shown in picture two where cut out of one machined piece. I still don’t like how little margin of error they allow for in these pieces. They have been cleaned up and primed in the third picture. The last picture shows holes that were used to match drill an upper fitting between the spars. These and additional holes also needed to be countersunk. |