|

|

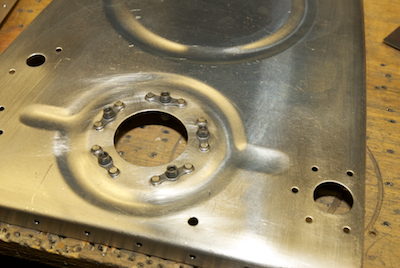

Kathy finished up the last of the dimpling of all the ribs, stiffeners, etc. and when she was done it was time for everything to take a bath. Before the bath, all the surfaces that would have sealant applied had been scratched up with scotch brite pads to make for a better bonding surface. You need to get all the parts clean, no scotch brite grit, grease or finger prints. After the bath, there was very little handling of the parts and then mostly with gloves. All the mating surfaces were also washed down with acetone before applying any sealant. These nut plates are for attaching the fuel level senders. |