Click a photo to embiggen |

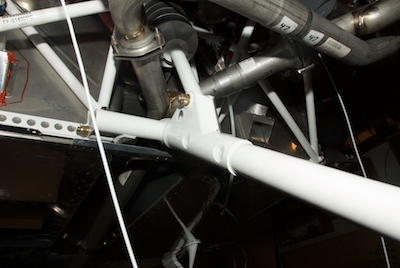

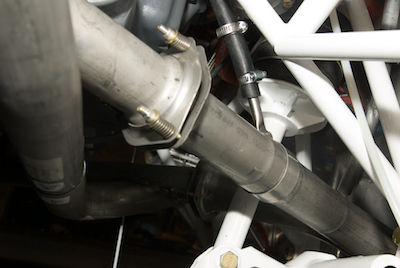

The tail pipe is tricky because it has to have the attached Y piece installed so that each side passes the nose gear suspension arm. So far, this is the only piece that has bit me because I was following my own build order. The plans have you do this before you attach the fuel line from the firewall fitting to the fuel pump. I had already installed the fuel line and when I inserted the tail pipe and tried to rotate it into position it could not pass between the fitting and the shock mount. I suppose it will fit without the hose but the clearance looks too small even it just the fitting is already in place. It was clear however that as I have it installed it would not rotate. I was perplexed about how I could support the fuselage so I could disconnect the nose gear and get it in place. I told Kathy I was perplexed and had already wasted a lot of time thinking about how to get past this. She then said “can’t you just use your shop crane to lift the front of the plane ?” Why yes, yes I could. In less than 20 minutes after starting this procedure I had disconnected the strut, gotten the tail pipe in position and reattached the strut. Then I moved on and attached the remaining exhaust system pieces. The last picture shows two things I had to do. There are two ball joint like sockets that need to have clamps attached to hold them together, one of which is visible. That pipe section also needed to be supported by a strut that attaches to the engine case and the exhaust with a section of rubber hose. I had to size and make all the pieces of the support to fit. |